Permitting

From air, water and pits to robust permitting for treatment and disposal, We manage all permitting stages from scoping, science studies, design, procedures, submittals, notifications, closure estimates and more.

Permitting Services

Bridging Goals, Needs and Success

When businesses need permits, authorizations, technical approvals and/or scientific support in order

to operate and profit, we provide the knowledge, experience and expertise to help.

Overview

We’ve been active for almost 40 years supporting client’s permitting and facility and system design goals. Here’s a quick partial view.

- E&P Solids & Fluids Disposal

- Class I, II Injection Disposal

- Treatment & Separation

- Recycling & Reclamation

- Cavern Storage/Disposal

- Road base Permits

- Hydrocarbon Recovery

- NORM Disposal, Decontamination, Remediation

Permit Types

- Injection Disposal: Fluids, Solids, NORM, SWD

- Salt Cavern Disposal

- Pits: Collecting, Washout

- Hydrocarbon Recovery; Road base reuse

- Treatment and Recycling; Drill Fluid Recycling

- Solid, Liquid Separation and Treatment

- Land Treatment / Land Farming

- Class I Industrial Treatment and Injection Disposal

- NORM disposal

- NORM Decontamination & Remediation

- NORM Fixed and Mobile

- Medical Device Registration

- Air, NPDES, SPCC, PPP

- USCG/EPA Vessel and Response Plans, ICP

Where

- International & Domestic

- Onshore, Offshore, Inland

- Gulf of Mexico

- TX, LA, NM, MS, AR

- UK, Africa, Middle East

Waste Types

- Oil and Gas Exempt & Non-Hazardous

- NORM

- Class I Industrial

- Hazardous

- Solid, Liquid, Oil

Oil and Gas and Industrial Permits

Oil and Gas and Industrial permits we’ve facilitated:

- Injection Drilling Permits

- Saltwater Disposal- Producing Formations

- Saltwater Disposal- Nonproducing Formations

- Solids Injection Disposal - Salt Caverns

- Solids Injection Disposal - Porous Formations

- Hydrocarbon Recovery

- Pit: Washout; Collecting

- Land Treatment & Land Farming

- Recycling and Separation Facility Permits

- Disposal Pit Permits

- Class II SWD Air Permits

- Class 1 fluid treatment and injection disposal

- E&P Drill Fluid recycling

- Stabilization and Landfill Disposal: Hazardous solids

- Stabilization and aggregate reuse: Non-hazardous solids

- Fluid Treatment and Discharge: Non-hazardous

- Salt cavern disposal, waste treatment, stabilization and: Hazardous and nonhazardous

- Hydrocarbon recovery: E & P solids and fluids

- Waste separation, aggregate recycling and disposal: Non-hazardous

- Class I Industrial Fluid Treatment and Injection Air Permit

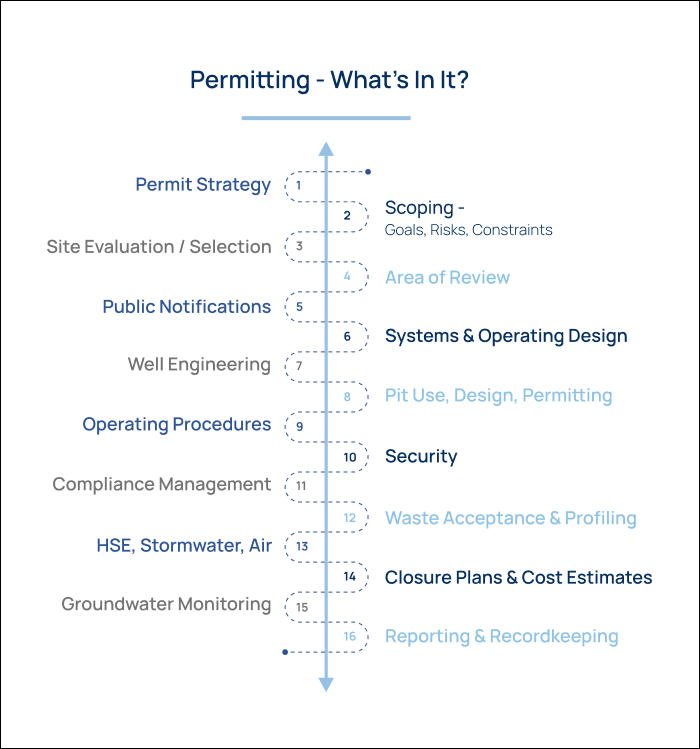

Permit Process and Technical Elements

Permits require that a lot of moving parts come together. We work closely with clients and their teams to effectively and successful bring it together successfully.

- Permit Strategy identifying goals and options

- Scoping risks, constraints, opportunities

- Site evaluations and selection

- Formation analysis for Capacity and confinement

- Formation analysis for Injection intervals and zones

- Formation analysis for site selection

- Well engineering: casing, cementing, perforations

- Soil and Hydrogeology Assessments and Reports

- Facility and System Design

- Waste Acceptance and Load Screening

- NORM Handling & Screening

- Waste Storage, Containment, Controls

- Facility Security

- Operating Procedures

- Area of Reviews (AOR) and Public Notifications

- Secondary permits for well drilling, pits, air, NPDES

- Reporting and Recordkeeping

- Closure Plans and Cost Estimates

- Facilitating Financial Security Instruments

Injection Disposal

Enpros specializes in solids and fluid injection disposal siting, permitting, and operations, including NORM. We’ve been actively involved in the safe disposal of > 45,000,000 bbls of E&P exempt, non-hazardous and NORM waste. We provide:

- Site Research and Suitability

- Formation analysis for Capacity and confinement

- Formation analysis for Injection intervals and zones

- Well Log interpretation for porosity, permeability, intervals, and confinement

- Zone analysis for operating criteria

- Marine shale suitability

- USDW and Hydrogeology analysis

- Well engineering: casing, cementing, perforations

- Plume and AOR analysis

- Systems design for solids handling and mixing

- Full permit management

Other Permits, Plans and Authorizations

Other plans and approvals we’ve obtained:

- Spill Prevention Control and Countermeasures Plan

- Pollution Prevention Plan

- Facility and Vessel Response Plans

- Facility and Vessel Security Plans

- Facility Security Assessments

- Waste Management & Operations Plan (LDNR)

- Responsible Carrier Programs

- Integrated Contingency Plans

- US Coast Guard Operations Manuals

- NPDES / LPDES Permits

NORM and Radioactive Material Licensing and Registration

Radiation related licenses and registrations we’ve facilitated:

- Mobile NORM decontamination and remediation

- Fixed facility NORM volume reduction, equipment and pipe decontamination

- NORM Disposal permitting

- Sealed source repackaging

- Leak testing of sealed sources

- Medical device registration

- Calibration source use and storage

Facility, Waste System and NORM System Design

Client’s often ask us to contribute to the design of their endeavors. Sometimes we design it all.

Facilities Designed

- Integrated fluid & solid E & P waste treatment, recycling & disposal

- Hazardous waste treatment and salt cavern disposal

- Class 1 wastewater treatment & injection disposal

- E & P waste separation, aggregate recycling and disposal

- E & P solids injection disposal facility

- E & P waste transfer station

- E&P Hydrocarbon recovery

Waste Systems Designed

- High volume solids offloading and transfer

- E & P waste mixing and slurrying

- Solids and Fluids subsurface injection systems

- E & P Solids separation and aggregate recovery

- Land treatment / Land farming pre-application waste processing

- E & P hazardous waste Landfill design

- Hydrocarbon recovery systems: solid and fluid streams

- Industrial wastewater treatment: neutralization; precipitation; filtration; oil-water separation; mineral balancing

- E & P phase separation (dewatering)

- E & P solid waste stabilization

- NORM volume reduction

Waste Testing -Oil and Gas and Industrial Class I

Onsite waste testing is often required to verify wastes are authorized for offloading and treatment / disposal at permitted facilities. We have designed and operated both commercial and onsite laboratories for the evaluation and management of oil and gas and industrial wastes.

Analysis

- Radioactivity concentrations in solids, liquids, and slurries via gamma spectroscopy multi channel analysis

- Radioactivity concentrations of airborne samples via alpha/beta scintillation

- Oil-Water-Solids via ASTM shakeout or conventional retort methods

- pH, conductivity, total dissolved solids

- Salinity, specific gravity

- Particle size distribution via sieve analysis

Key Features

- Nuclear and non-nuclear analysis

- NIST traceable standards for calibration of gamma spectroscopy, pH, conductivity, total dissolved solids and salinity instruments

- Commercial quality QA/QC, as appropriate

Regulatory Agencies

Agencies we’ve worked with and submitted permits, licenses and plans to:

- Environmental Protection Agency

- National Oceanographic and Atmospheric Administration

- United States Coast Guard

- International Maritime Organization

- US Army Corps of Engineers

- Federal Emergency Management Agency

- Uganda National Environment Management Authority

- Saudi Arabia Ministry of Environment, Water, and Agriculture

- Saudi Arabia Nuclear and Radiological Regulatory Commission

- Environment Agency, England

- Texas Railroad Commission

- Texas Commission on Environmental Quality

- Texas Department State Health Services

- Louisiana Department of Natural Resources

- Louisiana Department of Environmental Quality

- Louisiana Department of Health

- Arkansas Department of Health

- Arkansas Department of Environmental Quality

- Mississippi Department of Health

- Mississippi Oil and Gas Board